|

|

|

|

Jims RV-8

|

Date: 1-29-2014

|

Number of Hours: 2.20

|

Manual Reference: 7-11

|

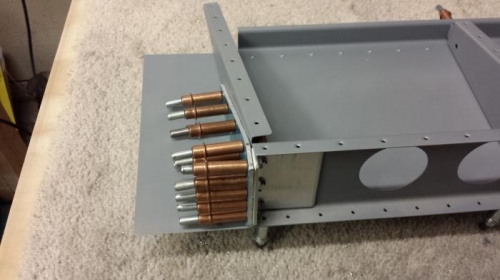

Brief Description: Bending flap support plate

|

|

So after some “other” stuff – I was back in the shop tonight. I dove right into the bending of the flap connector plate that rivets to the rib/spar/angle to really provide a beefy connection point for the flap actuator to grab on to. To visualize, since the inboard section of the flap is where the actuator arm is located, and because of the geometry of the fuselage at that point, the flap curves inward at the trailing edge. Therefore that inner-most rib angles toward the fuselage and support angle/plate need to angle too. The plans say to bend it 6.3 degrees… but I put the bend on it until It fit well into position with the angle.

The angle started off as a regular piece of aluminum angle that had to be measured, cut, and smoothed. With the band saw and the scotchbrite wheel, it was no big deal. After making the angle and bending the plate to 6.3 degrees J, it was just a matter of final drilling the parts and then deburring, smoothing them.

It was a big step tonight – now I need to make a flap cradle to hold the flap while riveting.

|

|

start with raw angle

|

|

measure, mark, cut, smooth, drill

|

|

cleco-ed up

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|