|

|

|

|

GA Aerospace’s Web Site

|

Date: 5-12-2018

|

Number of Hours: 24.00

|

Manual Reference:

|

Brief Description: Pages 24iS / U-03- 05 and 06

|

|

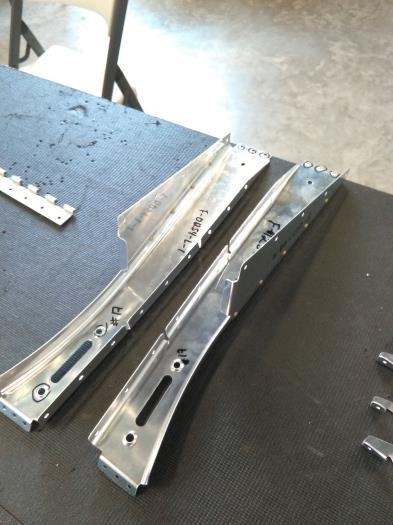

The steps 1, 2, 3, 4, 5 23iS-03 were carried out, in which countersink # 40 was made in the holes where the nutplates k1000-04 were placed in the part F-01205B-L-1 & R -1. and 6 countersink # 30 in 6 more holes in these piarts. Parts F-01205A-1 to F-01205B-L-1 & R-1 were riveted. In step 4 parts F-01205B-L-1 & R-1, F-01205C-1, F-01204K-L & R were riveted to parts F-01205A-1 and F-01204C-L & R. Finally, the parts F-01205D and F-01205D were riveted to F-01205A-1 with rivets LP4-3.

Steps 7 9 10 11 12 13 24iS / U-03 were also performed in which the parts F-1232B and F-01254A were separated.

In part F-01254-L-1 & R-1, dimpling # 30 was performed in 3 holes of the forward end and it was also opened to drill # 17 and 2 drill holes were dimpled.

In step 12, a break edge was made in parts F-01254A-L & -R. Finally, in step 13, part F-01254A-R was deburred, fastened and riveted to part F-01254-R-1, and the same was done for parts

F-01254-L-1 and F- 01254A-L.

Steps 1 to 5 24iS / U-05 were carried out, which started by marking a line in part F-1284-L & R in the forward face, after it was clamped with clecos the part was made match drill with parts

F-01207C -L-1 & R-1 to the fuselage to perform match drill 2 holes inferior to the parts F-1284-L & R usin the line previously marked as a guide. In step 4, the piece ES-00301 was riveted to the part F-01207C-L-1 and in the 5th part, drill # 19 was made to this same part.

Finally, steps 1 to 5 24iS / U-06, in which match drill # 30 in the F-12110 was performed in the F-01207C-L-1, were deburred and riveted with rivets LP4-3.

After step 5, dimpling was carried out in the holes where the rivets of the nutplates were installed, in step 6 part F-12111C was separated into two individual parts, then countersink # 30 was made in the 4 holes of each one of them. they, for this step, it was necessary to carry out the countersink manually because the diameter of the microstop beat with the angle of the piece.

Team: Andrea, Alvaro and Angel

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|