|

|

|

|

Sonex 815 Build Logs

|

Date: 2-23-2006

|

Number of Hours: 3.50

|

Manual Reference: F12

|

Brief Description: Forward Fuselage Side

|

|

Finished clecoing the details to the panel. Took about 1 hour to drill all holes to 1/8" dia. Only broke 1 drill bit (seems to be a problem only on drilling polished .032. Not an issue on the .025). All the drill bits broken so far were from The Yard. I ordered split point, but they aren't. They're unsplit, like wood drill bit style. Ok for final sizing, but I wouldn't want to start a hole that way. Anyway, dug out a few 6-year-old well-used bits. The first one was too worn. The 2nd worked ok, so I made it through all the rest of the holes with that. Those Yard bits are junk. Dangerous junk because getting bits stuck or flying debris is not a good situation.

Took about 1 hour to realize I had left off the doubler plate from the upper panel angle (around where the windshield frame passes through the upper angle). Drilled this, countersunk it, deburred, riveted it. Realized I left this off the RHS panel as well - I'll have to do that later. Shouldn't be too hard, but not as easy as if the upper angle was one piece in hand. Drilled, countersunk, and riveted the rudder pedal support angle pieces together (less than 1 hour). Spent another hour or so deburring all the F12 details and the skin panel. Got the whole thing deburred. Realized I left off the upper and lower firewall attach angles. I'll have to work those in on another day.

|

|

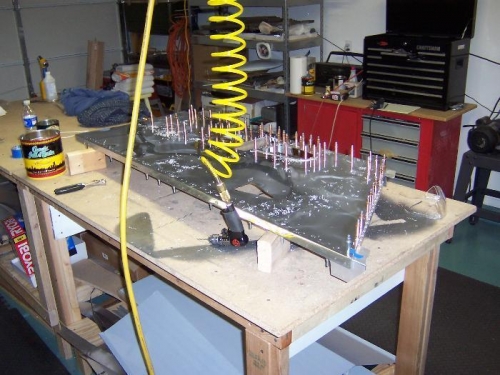

Drilling in process. Hung air hose from ceiling.

|

|

Not sure if I like that "lightweight" hose. Requires force to stretch it.

|

|

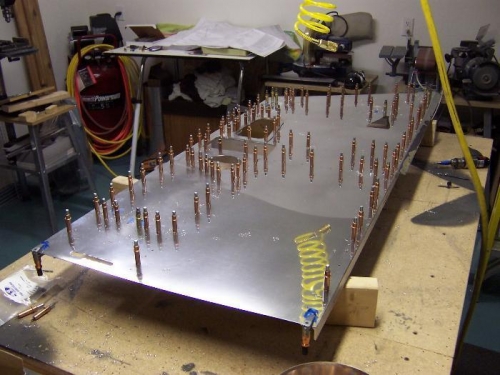

Looks like this was when drilling was done.

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|