|

|

|

|

Andrews Web Site

|

Date: 6-8-2020

|

Number of Hours: 2.00

|

Manual Reference:

|

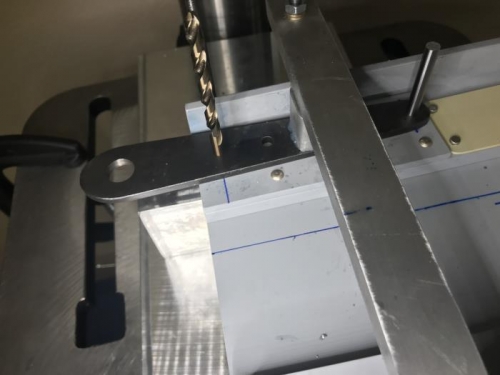

Brief Description: More Spar Drilling

|

|

I changed the setup on the drill fixture to drill the intermediate holes. As shown in the first picture, I only used one cross bar since this left room to get the chuck where needed while the fitting was firmly held with a D size drill and check pin. Next, drilling of the remaining two holes was completed. At this point, all the holes are drilled with a C size drill (0.242). My experience is that if I drill directly to the final drill size, the hole will be somewhat larger than the drill due to chips and who knows what else. At any rate, I did have a look at one of the fittings supplied by Mustang Aero that are match drilled to each other, to see if the holes I drilled through the stack are at least close to in line. Picture number two shows a C size drill going through easily. Maybe when the stack is opened to D size it will still be in line?? Now seems like a good time to try to justify my OCD on this topic. A "D" size drill is supposed to be 0.246 (+0. -.0007) an AN-4 bolt is supposed to be .246 - .249. That means that if you drill a really tight hole, the bolt should be a minor interference fit. But if your hole is even slightly too big, it could be sloppy. Next the fittings from Mustang Aero are pre drilled (both front and back fittings) that means that any misalignment, or wander in the drill bit has basically .003 at best and 0.000 at worst room for error. Yes, the stack is matched drilled, but we are asking for a lot in someone’s garage. This is the reason that I am using the original Mustang II procedure and using undrilled (blank) fittings on the backside.

|

|

|

|

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|