|

|

|

|

Conrads X-10 Build Log

|

Date: 2-12-2012

|

Number of Hours: 8.00

|

Manual Reference: Panel painting

|

Brief Description: anel Painting and Mpounting Dynon EMS module

|

|

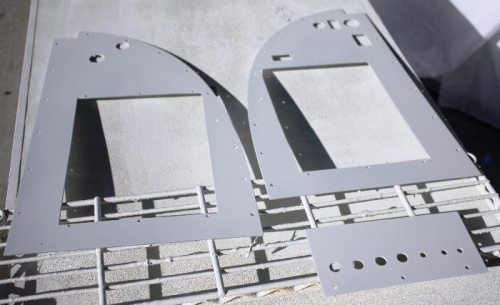

Feb. 11, 2012

I have cut most of the holes in the panel that I believe that I will need. So I began the painting process of the X-10 panel. I removed all the alodine coating, cleaned and primed with DTM white primer/finisher and final coated with Jet Flex White. I also permanently mounted with AN3 bolts, washers and AN960 nuts the Dynon SV-Engine Monitoring System or EMS module to the Radio Stack frame. This actually seemed like an excellent location if I need to get to any of the DB-25, DB-37 or 9-Pin Skyview System connectors to upgrade, test, trouble-shoot, modify or repair (maintenance) any of the pins or sensors. Also, I checked that the Van’s supplied rear seat shoulder harness cables do not interfere with the Dynon Air Data Attitude Heading and Reference System. (Which, by coincidence the Air Data Computer e.g ADAHRS is what I programmed at work on the AC-130H Spectra Gunship). They are ferrous and magnetic but unless there an inch or less from the ADAHRS the Directional Gyro / Compass Rose heading does not change. And I continue to work on little things, such as finalizing the Dynon Skyview cables, labeling and tiding up the wire, etc … that are necessary for the project to advance forward.

Time about 8 hours.

|

|

Pilot and Copilots Painted Panel with Switch Panel Drying in the Sun

|

|

Another View of the Panels Drying Between Coats

|

|

Dynon SV-EMS Mounted to the Radio Stack I

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|