|

|

|

|

Serenity

|

Date: 8-18-2007

|

Number of Hours: 1.50

|

Manual Reference:

|

Brief Description: Finished right flap

|

|

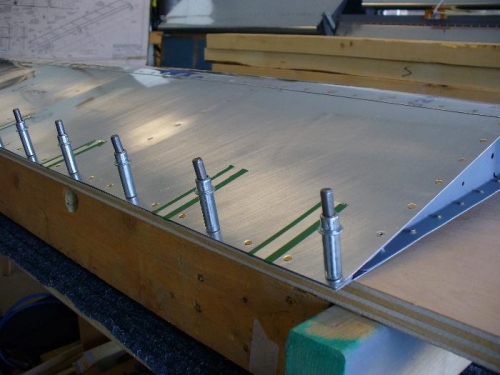

Riveted TE. Flap was dead flat, straight, no twist measurable. Some notes for builders - when the clecoes are removed from the TE and rivets placed, the TE becomes very warped until riveted. I used rivet tape to hold the TE together, as the clamps used on the L flap were clumsy. Worked great - after all rivets placed, I taped them down with a lengthwise piece, flipped the flap, and partially set the shop heads with the backrivet set (weight everything down well - I used jointed boards with bricks on top, held with clamps to the leading edge so the board/brick assembly wouldn't slide toward the trailing edge - pic 2). Flap flipped again topside up, then final flush set riveting with the steel plate compressing the shop head flush with the dimple. Make sure and keep the stell backrivet plate aligned witht he TE so the flush set can overhang a little and not strike the plate. Next - still have to rig the ailerons with pushrods, add my pitot and AOA lines I bought from SteinAir, add the conduit and wiring for lights, and will install servo tray in right wing for autopilot servo (can be added through access plate later, so don't have to leave bottom skin unriveted as they are now. But, i want to at least install the mounting plate now). Last step will be to rivet the bottom skins. Fuselage should be here in 2-3 weeks.

|

|

TE will warp when clecoes removed - taping edge worked great

|

|

|

|

Done.

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|