|

|

|

|

SeaRey LSX

|

Date: 7-27-2013

|

Number of Hours: 4.00

|

Manual Reference: Sect 18b

|

Brief Description: Airleron #2

|

|

Worked on Aileron #2... time consuming, messy, stinky, boring, me no likey.

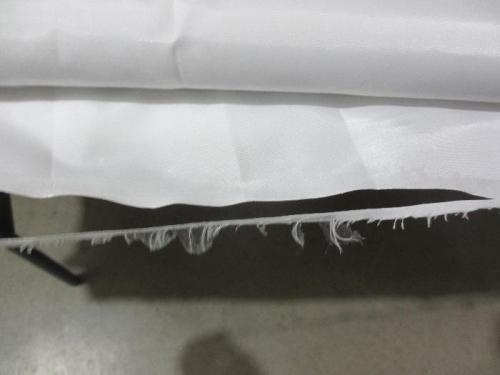

I will say that the Poly Fiber manual is well written and gives many tips. On the first aileron, I cut a section of fabric with what I thought was a clean cut, but as I worked with it, adding Poly Tak, I found that there was a lot of fraying. The manual mentions laying a line of polytak on the material prior to cutting to get a nice crisp edge, and what do ya know, it worked... Small wins...

I also noticed as I turned up the iron to 350 that where I had done a great job making sure I had a good amount of Poly Tak applied through all layers, I got a brown, crispy residue. I called Alan Chandler at PA and discussed with him, he says that is "normal", to just be careful not to overheat and try to clean up (carefully) with MEK on a rag - stay away from any places where you're supposed to be bonded to the structure or laps. The finish is much more important than the color, so don't let it goop up.

Lastly, I asked Alan about the leading edge ends (where large tube is) and the preferred method to finish the ends - he confirmed "flat". So, I'll have some touch up/rework to do to make it look "pretty"...

Word to the wise. If offered the option to receive built and finished wings... Buy It!

|

|

Some plane time

|

|

apply a line of Poly Tak prior to making cuts

|

|

Nice, non-frayed cuts

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|