|

|

|

|

My RV-8 Build Log

|

Date: 5-12-2018

|

Number of Hours: 6.00

|

Manual Reference:

|

Brief Description: Spinner Attach to Bulkhead, Gap Fillers

|

|

Located, marked and drill the #40 pilot holes for the machine screws that will secure the spinner to the bulkhead. Afterwards, drilled to #30 all 20 holes, 6 in the forward bulkhead, 14 in the aft bulkhead.

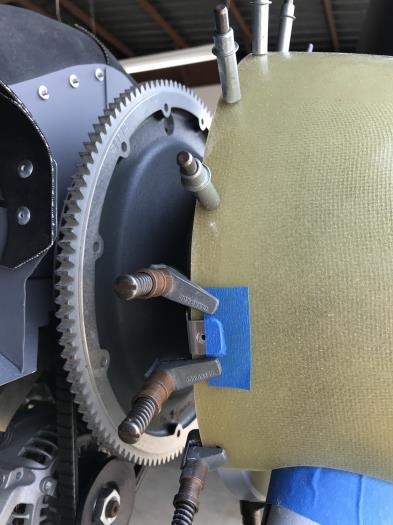

After securing the spinner, clamped boards to the prop blades and rotated to determine additional clearance requirements for the spinner. Contact was made, and I marked and estimated line to trim away. Removed the spinner and removed at most 1/8", with a decreasing amount as marked. After trimming both openings and sanding smooth, refitted the spinner to the bulkhead and re-tested the prop blade full rotation, and was somewhat surprised to find the first trim estimate was sufficient to provide the needed clearance.

Next, there are gap filler location behind the prop blade that are riveted to the sides of the rear bulkhead, with a support for a plate nut to be installed where another machine screw is used to attach the spinner. The plans call for .068 aluminum for the gap filler and support.

I decided to make templates from .032 aluminum... I first made templates from hard paper (again, from an old calendar), then transferred the template to the .032.

|

|

Spinner Attach Holes Located and Drilled

|

|

Determining Clearance Needed for CS Prop

|

|

Initial Gap Filler for Spinner

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|