|

|

|

|

Home of the Spodplane

|

Date: 8-30-2014

|

Number of Hours: 1.50

|

Manual Reference:

|

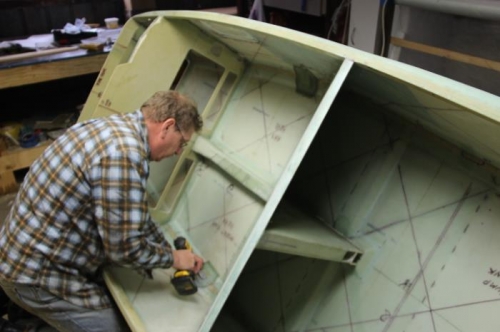

Brief Description: Outer seat belt mounts

|

|

Drilled holes for outer seatbelt mounts. Had a few problems, first holes I got the angle wrong, and made room for lots of flox. I won't say which seat :)

Technique that yielded the best results was to use the upright of the angle from the inside to drill out at the right angle, started with 1/16", then opened to 1/8".

Then counterbored from the outside, using a 19mm spade bit, taking the angle from a tentpeg pushed through the other matching hole.

Then opened up the hole from the inside in steps, using the AL angle as a guide. Reamed the first hole for each mount to 1/4". Located the angle using an AN4 screw, then reamed the other hole.

Made a bolt gauge/inserter from a 1/4" hardware bolt. Cut off square one end, and rounded the other. If it goes through the hole the next AN4 screw will.

Then noticed the plans screw size is way too short for the conterboring I did, so did some more. Plans don't mention that the back CAN'T be the same depth as the front, as the longeron is not exposed here so had to conterbore further to reach the same point in the longeron. (Holdover from Cozy MK I plans maybe). Still used a -18 screw in 6 locations, two with washers, and only 2 of the plans -16. Glad I bought extras in the size above and below, but should have bought a few dozen washers as well, in both sizes.

Overheated and killed two dremel grinding wheels when cleaning up the couterbores. Flox is hard.

|

|

First penetration of the side, most traumatic

|

|

Drilling some more

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|