|

|

|

|

Home of the Spodplane

|

Date: 2-6-2021

|

Number of Hours: 5.00

|

Manual Reference: 25-01

|

Brief Description: Finishing 101 - ailerons

|

|

410/micro had hardened enough to work after about 10 hours, but was much easier to work when fully cured the next day.

Sanded the port aileron bottom flat and trued the trailing edge a bit.

Just to try something different, prep sanded the starboard fuel drain fairing.

Discovered 1 pump of West 105 and 1 pump of hardener produces a reliable 35g of mixed resin, and two pumps does an aileron side.

Method:

Mix two pumps of epoxy

Stir and place a sample patch in the rough log

Paint part, squeegee off, rag off. Pour as much resin as I can into a micro/410 container, retaining the raw epoxy for prepping the surface for any excess filler. Don't add raw epoxy on top of filler when adding another coat.

Add 2:1 micro:410 in increments, and mix until a stiff creamy finish.

Squeegee on, screed off with a 200mm broadknife, pretending I'm plastering.

Did this for another coat on the aileron bottom, and first fill for the drain fairing. Prep sanded the starboard aileron bottom, and put the first coat of fill on it.

Used leftover filler to trial fill the pilot fuselage window frame

|

|

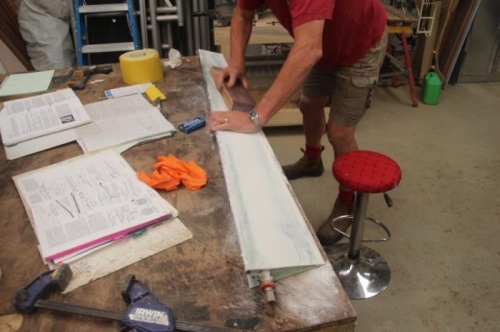

Sandy, sandy

|

|

Smeary, smeary

|

|

Screed it flat.

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|