|

|

|

|

Bobs Ten

|

Date: 7-23-2014

|

Number of Hours: 1.50

|

Manual Reference: 38-10.1

|

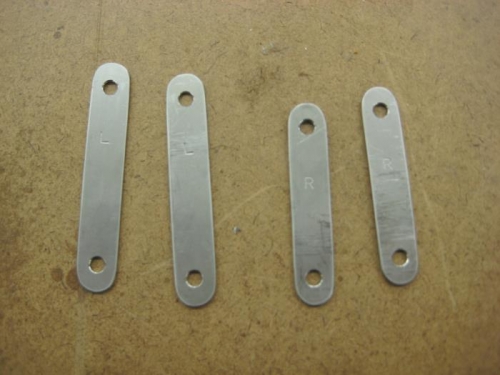

Brief Description: Fabricate Rudder Cable Links

|

|

1945 - 2115

Began finishing the 4130 steel cable links but noticed that the surface rust occurs very rapidly. I considered different methods of protecting the links while maintaining a decent appearance, as these will be seen. I did not think that any kind of paint would stand up to the abrasion of the rudder cable/pedal movement, so I decided to look at other suitable materials. After some research, I found A286 Stainless Steel. It is a corrosion resistant, strengthened stainless steel. A quick check at the material properties indicates that the strength and hardness of this steel is comparable to 4130. It has the corrosion resistance of 316 SS and Titanium has been added for strength. The bonus is that it looks good in it's natural state and will not have to be painted.

I had previously determined the lengths of the links with the 4130 steel, so using those for patterns, the stainless links were fabricated, in pairs, while clamped together.

Note: Working with Stainlles Steel requires special considerations regarding tool speeds and feed rates as well as lubrication and cooling.

Holes were match drilled using a #12 drill.

Ends of links were ground to a 1/4" radius.

All holes and edges were deburred and smoothed using a bench sander and s/b wheel.

The inside faces of each pair of links was stamped L or R for identification and orientation. When assembling the links, the stamped letters face each other, and are not visible from the outside.

Overall, the extra time spent yielded strong, corrosion resistant, nice looking cable links.

|

|

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|