|

|

|

|

Bobs Ten

|

Date: 3-26-2014

|

Number of Hours: 3.00

|

Manual Reference: 38-3.1>3

|

Brief Description: Modify Brake Pedal Installation

|

|

1330 - 1630

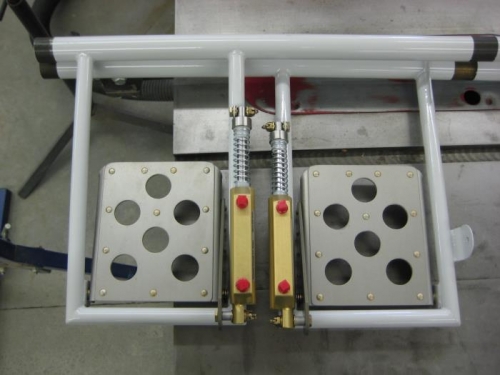

After assembling the rudder/brake pedals per the plans, it was noted that there was substantial pedal friction and that the internal master cylinder springs would be insufficient to prevent dragging brakes, I decided to modify the installation.

After researching the forums, I came up with the following installation.

First, the separate brake pedal pivot bolts were removed.

Drilled pedal pivot holes using #O, that is O not zero, drill. This allowed installation of SAE 841 bronze flange bushings in the pedal. The bushings were installed with loctite and a press fit. These bushings are graphite impregnated for continuous dry lubrication. I used McMaster part number 9440T63, eight were required.

Prepare pedal pivot rod. For this rod I chose 3/16" (.1875) Multipurpose O1 Tool Steel, (drill rod). McMaster part number 8893K178. Each pivot rod was cut to 6 3/8" length, deburred, and ends chamfered.

The rods are retained using 3/16" set screw shaft collars, McMaster part number 6432K19. Eight collars were required.

The rods were then inserted in place of the previous pivot bolts, and centered. Small flats were ground in the rod where the collar set screws were located.

Install each of the brake pedals using specified washers, drill rod, and shaft collars. Loctite was used on all set screws.

To ensure brake pedal positive return, external springs were fitted to the master cylinders. I used nylon flange bearings, McMaster part number 6389K625, to protect the shafts and center the springs. Eight bearing were required.

The springs were McMaster part number 9657K432. Four were required.

A stainless set screw shaft collar was used as a fixed bearing surface for the spring/bearing assemblies. McMaster part number 6462K14. Four were required.

Master cylinders were reinstalled with external spring assemblies over shafts.

Plan specified bolts were used, tightened to eliminate side play, and saftied with cotter pins, per plans.

Movement was checked for clearance a

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|