|

|

|

|

Bobs Ten

|

Date: 8-7-2013

|

Number of Hours: 1.30

|

Manual Reference: 36-2.4>6

|

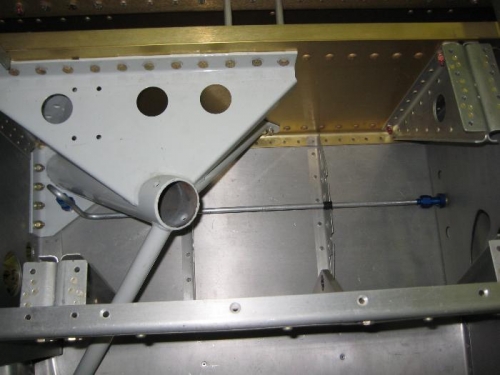

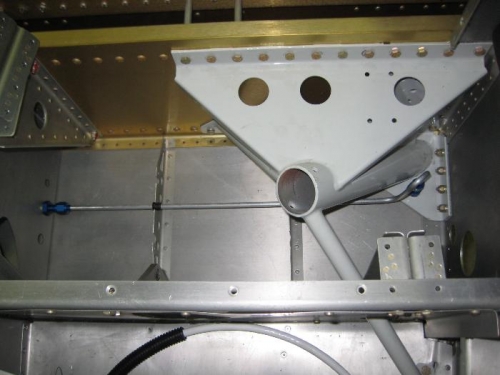

Brief Description: Fabricate Bulkhead to gear Leg Brake Lines

|

|

1312 - 1400 1436 - 1506

Returned from Oshkosh with a 180 degree tubing bender. After testing it out on some scrap tubing, I decided to scrap the previously made brake line and fabricate a new one using the new bender. I was able to make the lines using only 2 bends. Much cleaner and efficient install.

Using 5052 aluminum tube, deburred, cut, and polished one end.

Double flared end using Mastercool tool.

Installed fitting sleeve and nut.

Bend tubing 180 degrees using bender, starting the bend 2 1/8" from lip of flare.

Bend tubing 90 degrees, 45 degrees from plane of 180 degree bend. This bend is completed such that the bottom surface of the tubing is flush with the lip of the flare, as in photo 1.

Install snap bushings, nut, and sleeve onto tubing.

Mark and cut tubing to fit inside tunnel wall.

Temporarily install tubing on gear leg fitting.

Mark tubing at tip of tunnel wall fitting.

Remove tubing.

Add aproximately 3/16" to mark for material needed to double flare tube.

Cut tube at this mark, debur, and polish tubing end.

Double flare tubing end.

Install brake line and verify fit.

Repeat for right side.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|