|

|

|

|

Safari Helicopter Construction

|

Date: 2-25-2006

|

Number of Hours: 6.00

|

Manual Reference: N/A

|

Brief Description: NDT and Shot Peening

|

|

At the facility where I work I have various special processes available to me such as Magnetic Particle (Magnaflux), Liquid Penetrant Inspection (Zyglo), Shot Peening, Dry Film Lubricants and just about any aerospace coating that can be shot thru a spray gun. My main job function is Quality Control manager and NDT Level III. As busy as we are now, about the only time I can work on my parts is on the weekends. Our shop holds most of the major airframe approvals (Boeing, Bell, Eclipse, Raytheon, etc) so I find it a great advantage to use these processes on my kit built helicopter. The use of the NDI methods is obviously to find surface and subsurface flaws, especially in the welded components. The Shot Peen process at first glance looks a whole lot like a glorified sand blasting cabinet. The difference lies in that Shot Peening is not used for cleaning. The process uses finely divided, carefully sized steel shot of a certain hardness to induce a beneficial compressive stress in the surface of the part. The compressive stress resists the formation of fatique cracks. The process is tighty controlled and closely monitered using only certified technicians.

|

|

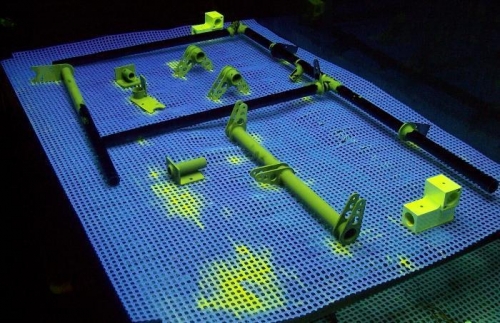

Flight Controls getting Liquid Penetrant Tested

|

|

Shot Peen Machine

|

|

Pylon Struts, Stab Support after Shot Peening

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|