|

|

|

|

Terrences Web Site

|

Date: 12-6-2012

|

Number of Hours: 3.00

|

Manual Reference: N/A

|

Brief Description: Practice oval cut in .040 & remove rivets

|

|

Practice oval cut in .040 & remove rivets

1. I've tentatively decided to put the left wing together, pretty much completely, and then to do the right wing. The primary reason is that I have a new, un-drilled skin for the right wing, and that will be a bother to work with. So, I believe that it will be better to put the left wing together, thus re-familiarizing myself with all the issues of wing construction before I begin the right wing. Hopefully, I'll thus gain some fabrication efficiencies in that everything I do on the left wing will apply to the right wing, but only some of what I do on the right wing would apply to the left wing.

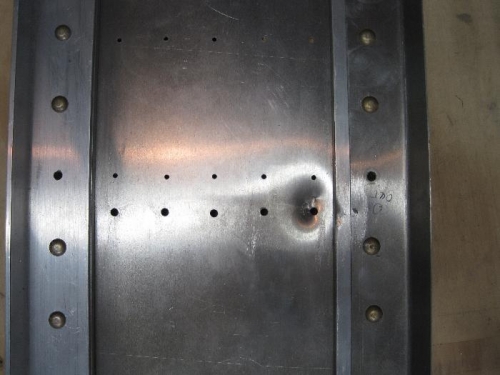

2. The repair to the left spar web will require cutting out an oval of badly bulged material, see, fig. 1 which shows the original damage. it was not possible to flatten that region, so I am going to cut out the bulged area and then fill that with a shaped plug (shim) so that the rivets will have something to hold to. I will also put on a doubler on the front of the spar, similar to the one just riveted to the right spar, except a bit wider so that the doubler will engage 4 rivets on the spar cap. I practiced cutting oval holes in a piece of 0.040 scrap using a rotary file. In the past I have used an electric drill to spin my rotary files. Mel suggested using a die grinder, instead. I practiced with my pneumatic die grinder and it was much easier to control the cut than with the electric drill.

3. I mounted the left spar to my table using the jigs described earlier and removed 5 rivets from the spar caps to clear the location for installing the doubler.

|

|

Damage to web of left spar

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|