|

|

|

|

Terrences Web Site

|

Date: 6-13-2008

|

Number of Hours: 6.00

|

Manual Reference: N/A

|

Brief Description: Make up 22 rivet strength test specimens

|

|

Rivet strength specification for submittal to Mark Sensmeier and Jim Helbling, for their analysis for the Zenith Builders Analysis Group.

The Specs called for strips of 0.025" 6061-T6, 40 x 160-mm, 3 rivets with 20-mm edge spacing, with tolerance ±1-mm. Produced set of 5 with A4, A5, and AS5 rivets. All rivets supplied by ZAC with delivery in February 2007. Aluminum supplied by Air Parts, Inc, Kansas City, MO, with delivery in early 2007.

1. Cut the strips from sheet aluminum.

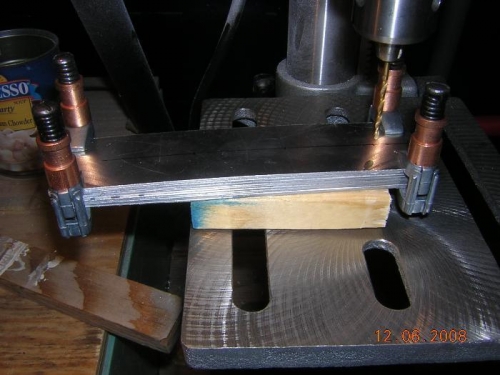

2. Clamp half of strips together as shown in Fig. 1, and pilot drill 3/32" .

3. Clamp 2-strip assemblies, and drill to final diameter, following usual drill, cleco, drill, cleco, etc. pattern.

- to 3/32" and then #30 for A4 specimens

- to 3/32" and then 1/8" and then #20 for A5 and AS5 specimens, sequence Nos. 01-08 and 01-05 respectively

- to 3/32"and then 1/8" and then to #16 for A5 specimens, sequence Nos. 09-10

4. Except for A5 specimens 06, 07, and 08, deburr

5. Prime wtih Cortec 703

6. Rivet specimens, A4, A5, or AS5, with following changes from standard procedure:

- A4 specimens 06 and 07 rivet using A5 modified rivet head

- A5 specimens, 06-08, rivet w/o deburring

- A5 specimens, 09-10, rivet A5, but the #16 holes are 10% larger diameter than standard #20 holes.

7. Number specimens per specs.

|

|

Clamped stack to pilot drill

|

|

Drilling final holes

|

|

A4, A5, and AS5 specimens

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|