|

|

|

|

Terrences Web Site

|

Date: 8-22-2007

|

Number of Hours: 4.00

|

Manual Reference: 6T2A 4-5

|

Brief Description: Rivet stabilizer bottom skin

|

|

1. I riveted the bottom stabilizer skin to the skeleton, except for 4 rivets that were so close to the attachments that I could not put my HF rivet gun onto the mandrel and hold the gun normal to the surface.

2. The PAM's suggestion of clecoing every 3rd hole, then placing rivets in all the remaining holes, popping all those rivets, removing clecoes, and popping the remaining rivets worked quite well and was much more efficient than popping each rivet after it was placed.

3. The rivet gun had trouble popping the rivets. All rivets required at least 2 pops, many required 3 or 4, and way to many required 6 or 7. I tried a few things to get the gun working better:

a. I added several drops of oil to the air intake--did not help.

b. I simplified the air hose set up (by removing the quick disconnect, the swivel joint, and the small diameter coiled hose) to try to reduce pressure drop between the compressor and the gun--did not help.

c. I re-primed the air chamber per the instructions--did not help.

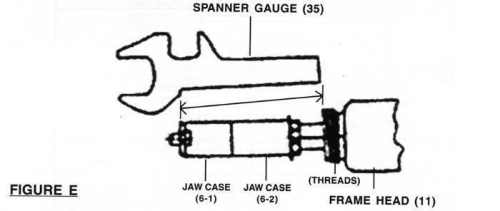

d. I searched the Matronics archives for posts that I recalled about this problem within the past 6 months or so. I found a post by Bill Naumuk dated 4/16/2007. Bill found the problem was caused by the jaw cases (6-1 and 6-2) loosening and separating. Disassembly of my riveter revealed exactly the same problem. I tightened the jaw cases together and the adjusted for clearance using the supplied spanner gage. Then I tested a few A4 rivets on a piece of aluminum flashing. It worked nearly perfectly. Typically two pops were required. See Image 1.

e. I replaced the quick disconnect, but decided to leave off the swivel joint. I tested the riveter with and without using the coiled hose and determined that the small hose did not affect riveter operation once the jaw cases were appropriately tightened.

f. The 4th hour was time spent debugging the HF riveter.

4. I determined that my hand operated riveter would work on the rivets by the attachments. I sent the A4 and A5 nosepieces for the hand riveter to ZA

|

|

HF Riveter jaws

|

|

Riveted stabilizer bottom

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|