|

|

|

|

DONALD'S WEB SITE

|

Date: 7-19-2010

|

Number of Hours: 2.25

|

Manual Reference:

|

Brief Description: Elevator skins cut to size

|

|

I cut the elevator skins to size tonight. When I did the rudder I did it with snips. This time I decided to use the bandsaw to make it easier and more exact. When I was doing the rudder I had a 6 TPI wood blade on the bandsaw (which Sonex says is fine)...I tried a bit of cutting on the rudder with it and the cuts were very rough and the saw had a lot of chatter.

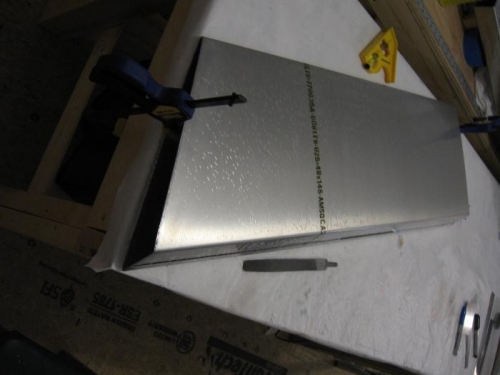

Now I have an 18 TPI metal cutting blade on the saw, and it cuts like a laser. Fast, straight, little effort required and almost no material lost/destroyed. Because I only have a 9" bandsaw, I had to lop off part of the end of the skin before the portion where the real angles cut would fit under the blade (pic 1). I also got some interference from my drill press, which is mounted nearby. I worked around it, but I might think about moving the press farther down the workbench...

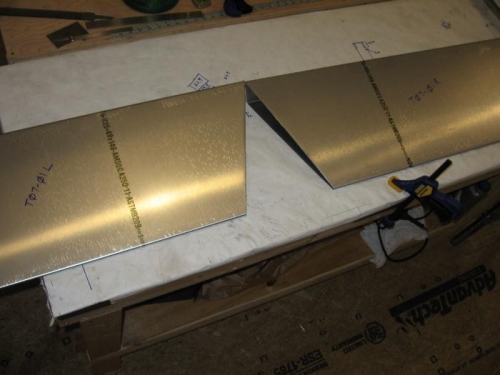

Once the skin was cut on the bandsaw as close to the lines as I dared, I moved the skins to the work tables, clamped them down, and went to work on them with a fine file, 150 grit sandpaper, and scothcbrite pads. In the end both skins turned out great, some of my best work so far!

|

|

bandsaw elevator clearance

|

|

elevator skin clamped to bench for filing/finishing

|

|

completed left & right elevator skins

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|