|

|

|

|

Rogers Web Site

|

Date: 9-14-2014

|

Number of Hours: 6.50

|

Manual Reference: 8-21/23

|

Brief Description: Tailcone bulkheads

|

|

Today, I had a pretty successful day, managed to get a bit done.

I marked out the separate parts that make up the F-800, and cut them into their separate parts. So I ended up with the two rudder stops (F-886 R and L), two angles (F-810C and F-811C) and the angle/control stop (F-812B). I then edged and deburred these parts. The two angles F-810C and F-811C also had to be radiused so that they would fit inside the top longerons.

I clecoed the F-812A and F812C bulkheads together, and drilled the common 1/8th holes between these parts to full size. I used a seamer to bend the flanges of the F-812A so that they were inline with the flanges of the F-812C bulkhead, when looking from the top of the bulkhead downward.

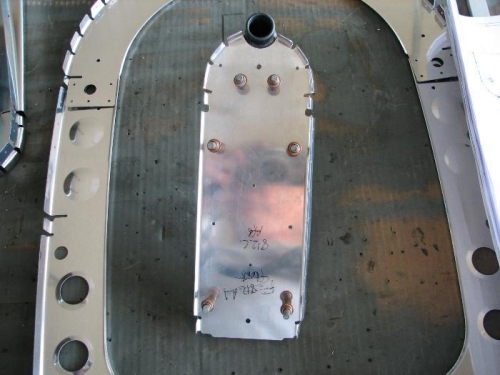

I marked the vertical position of the WD-409 Tail Spring on the front side of the F-812 bulkhead assembly, this gives you a horizontal line. I clamped the WD-409 in place, and then match drilled the two ‘keeper’ rivets, through the bulkhead assembly and the WD-409 tail spring mount. I machine countersunk the ‘keeper’ rivet holes on the AFT side of the bulkhead assembly.

I unclecoed the assembly, deburred the rivet holes and edges, I dimple countersunk the common #30 rivet holes between the two halves of the bulkhead, so that the flush face is on the aft side of the assembly. I then primed the contact surfaces of the tail spring mount and the two mating surfaces of the bulkhead halves. I then riveted the two halves of the F812 bulkhead assembly together, but only using the dimpled rivet holes.

I cut the stab attach bars into their two parts, I then radiused the corners and edged them.

I roughly cut out the shaded area depicted in the plans from the F-811A and 811E bulkheads. These bulkheads were them clecoed together, along with the two stab attach bars and the F-811C angle. Then all 1/8th holes were drilled to full size using the bulkheads as a pattern, as the stab attach bars didn’t have a full complement of pre drilled holes and had to be drilled through. I again used a seamer

|

|

The F-812 bulkhead Ass clecoed to the tail spring mount.

|

|

I clecoed the mid fuse bulkheads and armrests back into place.

|

|

Loads of shiny bulkheads

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|